Understand the Various Perks of Hiring Oil Water Separator Manufacturers and its Benefits

Compressed air systems will be successfully optimised by oil water separator manufacturers while continuing to adhere to environmental waste from industries' disposal laws. Systems for compressing air are essential in many commercial manufacturing cycles. Poorly operated air compressors may be destroyed by impurities that accumulate throughout production, despite their great value to manufacturing.

Sediment traps are settling ponds created by excavation and/or an embankment that catch and hold runoff that is heavily loaded with sediment from a building site for long enough for the majority of the silt to settle out before the site is released.

Small Sedimentation Trap's Goals and Methods of Operation

By capturing and holding site runoff, sediment traps, and basins enable soil particles to settle out before release. On a site, sediment traps may be used to service a number of minor catchments, storing runoff with the help of foundations and other barriers before releasing through an armoured overflow, a piped outlet, or another drainage feature onto a vegetated swale.

They stand as one of the most dependable and efficient methods for treating runoff from building sites that contain silt. These buildings are generally located close to the site's edge, where flows gather in swales, canals, or other low spots. The next section discusses certain factors linked to site compliance and permit applicability.

Observance of Safeguarding the Environment Laws

With soil and water body pollution being key problems, oils, and wastewater may harm the environment severely. Operators of air compressors can avoid environmental pollution by utilising effective oil-water filtering systems. Additionally, it enables them to follow the environmental protection laws in the regions where their enterprises are located.

Unlike sediment traps, sediment basins often cover a wider area. They may also include earthen embankments that hold onto runoff for a longer length of time before releasing it through risers that are floating, perforated, or slotted, or by floating skimmers that collect cleared water from the surface.

Understand What is the Benefit An Oil Water Separator?

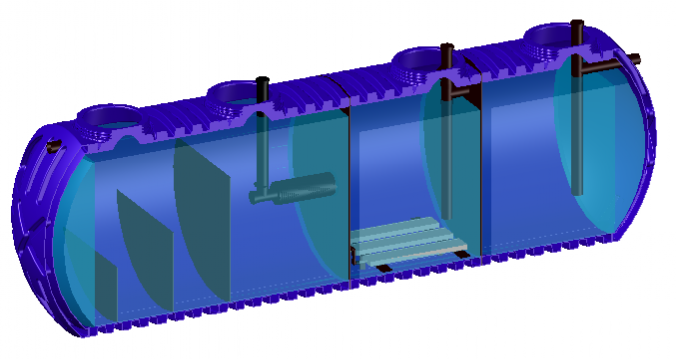

Waste oils produced during industrial manufacturing processes are eliminated using an oil-water separator. This equipment, also known as a condensate separator, helps separate lubricants such as oils and other liquid lubricants from condensed water produced by large-scale air compression operations.

Operators can comply with municipal wastewater rules by draining water devoid of oil in this way. They can be built as bigger sediment basins to handle mass grading runoff from roads, commercial/institutional locations, or smaller sediment traps to serve disturbed regions under five acres.

Comments

Post a Comment